Since the creation of Shell-O-Matic, we have built nearly 1000 slurry tanks so we know there is much more to it than a simple rotating drum with a paddle.

First, we pay attention to providing our customer with rugged and reliable driving mechanisms to ensure their tanks never stop. Second, we know that slurry material is expensive and probably the most important and sensitive component of the shell building system, so we provide you with all available options to measure, control and maintain the slurry quality.

This includes:

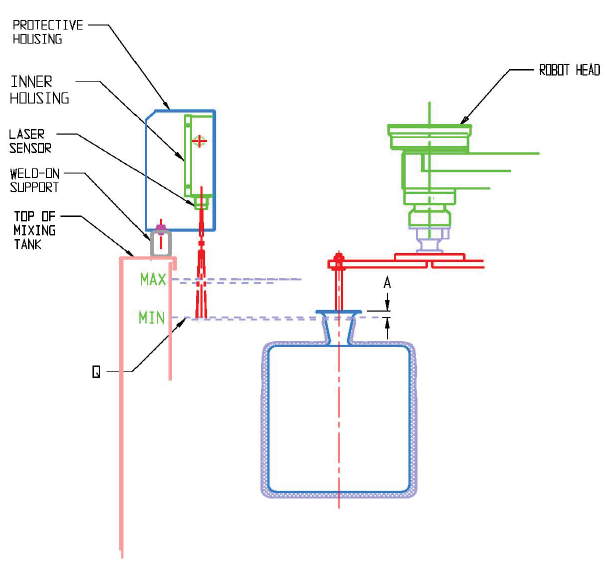

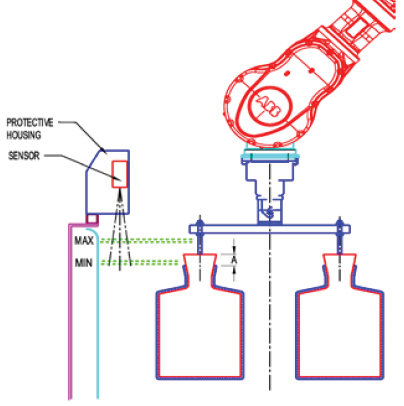

- Level sensing and control of the robot to maintain constant dipping depth

- Rotating speed adjustment

- Real time viscosity sensing

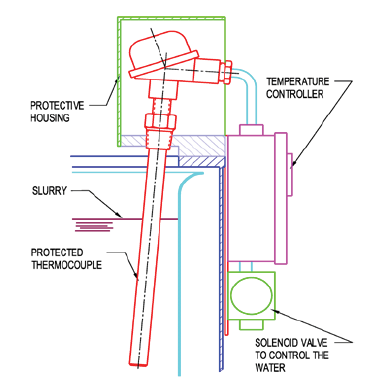

- Temperature sensing and control through a water-cooled paddle

- Automatic cover that opens only when parts need to be dipped

- Vacuum slurry tanks if needed

To ensure ease of cleaning we can also provide a variety of plastic covers and liners, including one-piece plastic liners for the tank interior. Furthermore, all wetted parts of the tank are made of high-quality stainless steel.

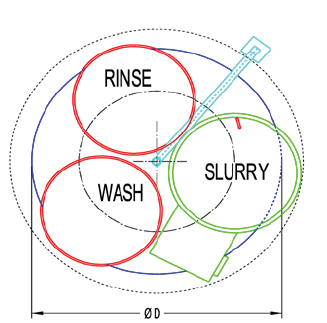

We can also provide turntables that can hold many tanks and position the one needed for the robot area, thus allowing a smaller envelope robot to access a plurality of tanks. If you need to move the tank around, we can build it on an air cushion, making it easy for an operator to displace it.

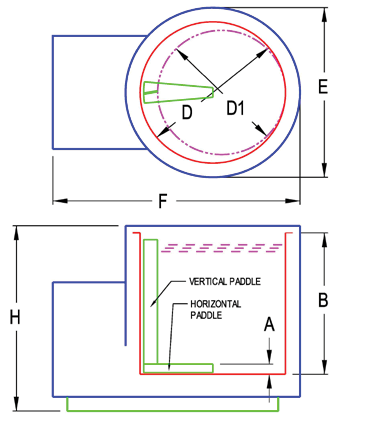

| tank size d | d1 | a | b | e | f | h | slurry volume | |

|---|---|---|---|---|---|---|---|---|

| liteR | us gal | |||||||

| 36” 915 mm |

31" 785 mm |

3” 75 mm |

33.12” 840 mm |

40” 1016 mm |

58” 1475 mm |

44” 1118 mm |

540 | 142 |

| 41” 1040 mm |

36” 915 mm |

3” 75 mm |

33.12” 840 mm |

45” 1140 mm |

63” 1600 mm |

44” 1118 mm |

700 | 185 |

| 43” 1090 mm |

38” 965 mm |

3” 75 mm |

33.12” 840 mm |

46” 1170 mm |

63” 1600 mm |

44” 1118 mm |

772 | 204 |

| 48”-L 1220 mm |

42” 1067 mm |

3” 75 mm |

33.6” 854 mm |

51” 1295 mm |

63” 1600 mm |

44” 1118 mm |

960 | 254 |

| 48”-H 1220 mm |

42” 1067 mm |

3” 75 mm |

37.4” 950 mm |

51” 1295 mm |

75” 1905 mm |

44” 1118 mm |

1070 | 281 |

| 54”-L 1370 mm |

48” 1220 mm |

3” 75 mm |

31.5” 800 mm |

57” 1448 mm |

78” 1980 mm |

44” 1118 mm |

1111 | 293 |

| 54”-H 1370 mm |

48” 1220 mm |

3” 75 mm |

36” 915 mm |

57” 1448 mm |

78” 1980 mm |

49.2” 1250 mm |

1295 | 342 |

| 60”-L 1525 mm |

54” 1370 mm |

3” 75 mm |

31.5” 800 mm |

63” 1600 mm |

81” 2060 mm |

44” 1118 mm |

1370 | 361 |

| 60”-H 1525 mm |

54” 1370 mm |

3” 75 mm |

40.2” 1021 mm |

63” 1600 mm |

81” 2060 mm |

49.2” 1250 mm |

1597 | 422 |

| 62” -L 1575 mm |

56” 1425 mm |

3” 75 mm |

34” 865 mm |

66” 1675 mm |

98” 2475 mm |

46” 1175 mm |

1529 | 402 |

| 62”-H 1575 mm |

56” 1425 mm |

3” 75 mm |

47” 1195 mm |

66” 1675 mm |

98” 2475 mm |

59” 1500 mm |

2172 | 572 |

| 67” 1700 mm |

60” 1525 mm |

3.5” 90 mm |

42.5” 1080 mm |

71” 1803 mm |

102” 2590 mm |

59.25” 1504 mm |

2160 | 568 |

| 72” 1830 mm |

64” 1625 mm |

7” 180 mm |

52” 1320 mm |

80” 2030 mm |

109” 2770 mm |

74.5” 1890 mm |

3274 | 862 |

| 75”-L 1905 mm |

66.5” 1670 mm |

4” 100 mm |

48.5” 1232 mm |

81” 2057 mm |

105” 2667 mm |

54.75” 1390 mm |

2700 | 710 |

| 75”-H 1905 mm |

66.5” 1670 mm |

4” 100 mm |

60” 1525 mm |

81” 2057 mm |

105” 2667 mm |

71.8” 1825 mm |

3700 | 975 |

| 88” 2235 mm |

** | 95” 2415 mm |

125” 3175 mm |

|||||

| 100” 2540 mm |

** | 106” 2695 mm |

138” 3505 mm |

|||||

Standard features

- Removable, L-shaped paddle

- On/off switch

- Overload protection

Options:

- Variable speed

- Slurry level sensing

- Remote start/stop

- Automatic cover

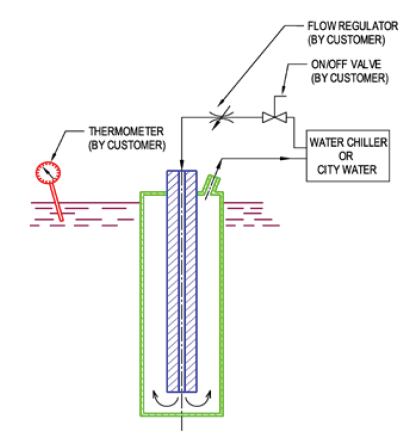

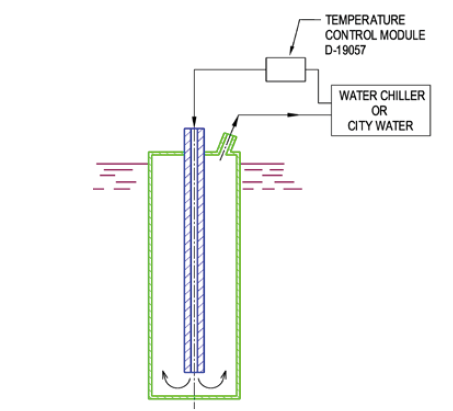

- Water cooling

- Plastic liner

- Temperature controls

- Full plastic tank

- Zero speed detection (alarm)

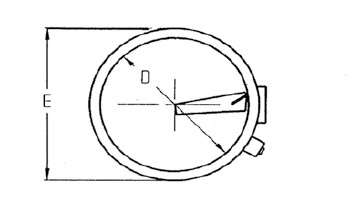

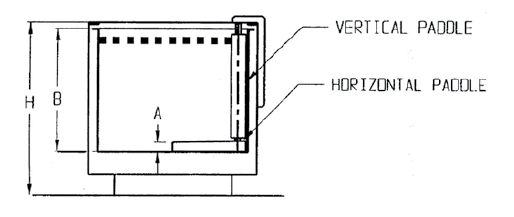

| tank size d | e | a | b | h | slurry volume | |

|---|---|---|---|---|---|---|

| liteR | us gal | |||||

| 24” 610mm |

28” 710mm |

2.5” 64mm |

27” 685mm |

37.75” 960mm |

185 | 49 |

| 30” 760mm |

34” 870mm |

2.75” 70mm |

28” 710mm |

38.75” 985mm |

300 | 78 |

| 32” 810mm |

36” 910mm |

2.75” 70mm |

29” 735mm |

40” 1015mm |

353 | 93 |

| 36” -L 915mm |

40” 1016mm |

3” 75 mm |

25” 635mm |

38.75” 985mm |

380 | 100 |

| 36” -H 915mm |

40” 1016mm |

3” 75 mm |

30” 762mm |

43.5” 1104mm |

465 | 122 |

| 47.5” 1200mm |

52.7” 1340mm |

3.8” 96mm |

41.6” 1056mm |

57.5” 1460mm |

1085 | 285 |

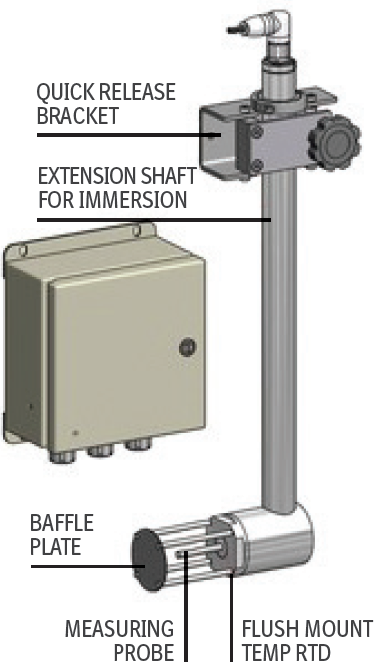

Viscometer

The AST-100IPRI Viscometer is inserted into the slurry and outputs continuous measurement of viscosity and temperature.

The instrument enables automatic viscosity control and improved quality assurance over cup method.

Benefits:

- Correlates with lab viscometer and cup measurement

- Enables continuous logging of viscosity and temperature

- Alarms for “off-spec” slurry condition

- Improves stucco coverage and optimizes drying time

- Reduces cracking, excess metal, burn in and penetration

- Minimizes operator involvement

Features:

- 316SS construction with baffl e plate for abrasion protection

- Easy cleanable design with no moving parts

- Internal RTD eliminates slurry build up

- Viscosity & temperature outputs as 4-20mA, RS-485 & RS-232

- Fully tested for future QC checks

Options:

- AST-310SY-420 controller for closed loop viscosity control

- Quick release bracket for inspection and cleaning

- Manual and wireless data logging options

- 115VAC, 230VAC or 24vdc power input options

Automatic slurry level sensing

The robot follows the slurry level and maintains a constant shell dimension “A”.

When the minimum slurry level “Q” is reached, the robot will stop at the end of the cycle and give an alarm signal.

The operator then ads slurry to max. level (using a pump, by gravity or manually).