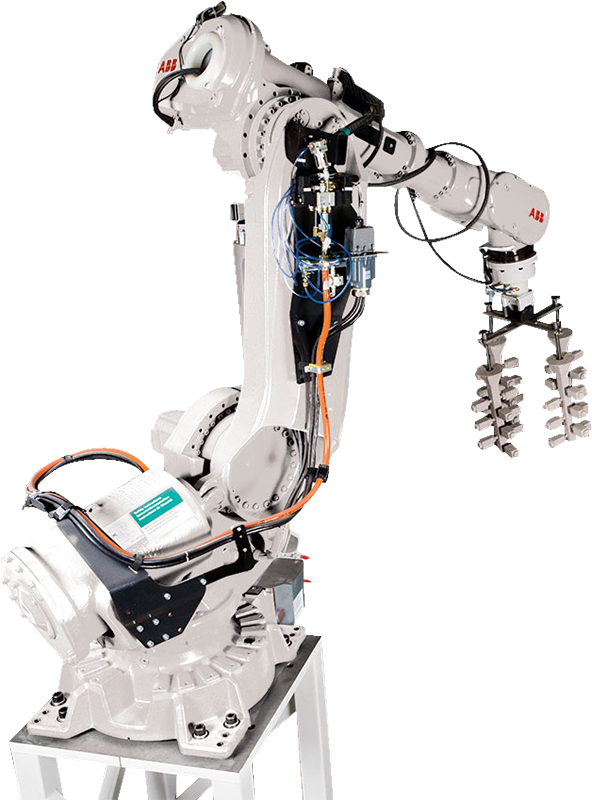

The articulated robots offer a high degree of flexibility. Typically they have six axes; a seventh axis traverse drive is available to move the entire robot back and forth.

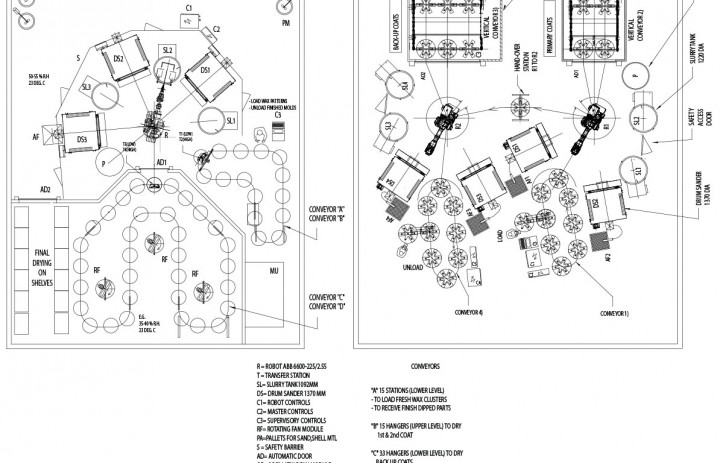

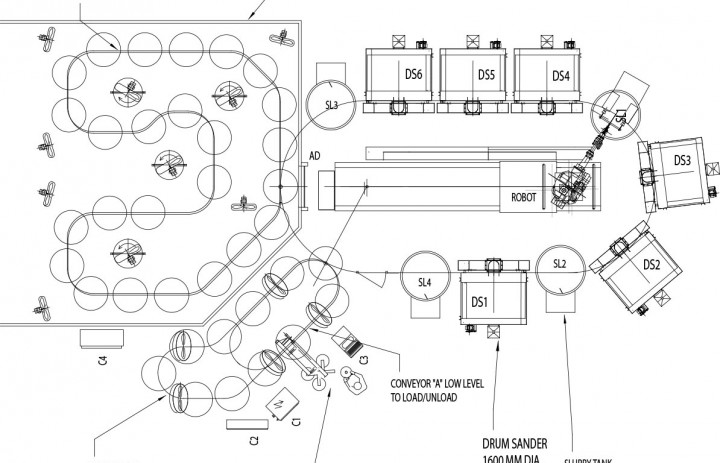

Shell-O-Matic has been integrating robots for the investment casting industry since the early ’70s. With over 300 systems installed everywhere in the world, our specialists can offer you a robotic solution tailored to your needs. We offer our clients a turnkey solution, from the design of an automatic mold-making system to the installation and training of your technicians. We can design a wide range of systems from simple to complex, and from small parts to very large and heavy part clusters.

Shell-O-Matic is renowned for having made some of the biggest systems in the world capable of handling heavy parts with very high production rates. Our application engineers also work with your team to optimize equipment productivity and minimize the footprint by adapting the control systems strategy and wax tree clustering.

With many of our team members having over 35 years of experience in robotic integration for shell room, we also pay attention to the small details, making sure the robot motion is friendly on the wax clusters and on ceramic shells, thus producing the same constant quality every time. We can offer you:

- Wide range of 6-axis ABB robots of various working envelopes and load capacity.

- Shell-O-Matic’s traverse axis (7th axis) to extend robot working envelope when dealing with complex shell-making systems. Proprietary design that is rugged for the foundry environment and thus outperforming standard 7th axis from generic robot makers.

- Multi robot integration to maximize your factory throughput.

- Industry-renowned gripper systems selected or adapted to your needs. Proven designs with many grippers having more than 25 years of continuous operation.

- Integration of the robot with the surrounding process equipment (including existing equipment used in your factory).

- Capacity to integrate or work with all robot brands.

- Simple human machine interface in the language of your choice.

- Robot cell safety system matching your local safety codes.

- Worldwide training and support by Shell-O-Matic investment casting robotic experts.

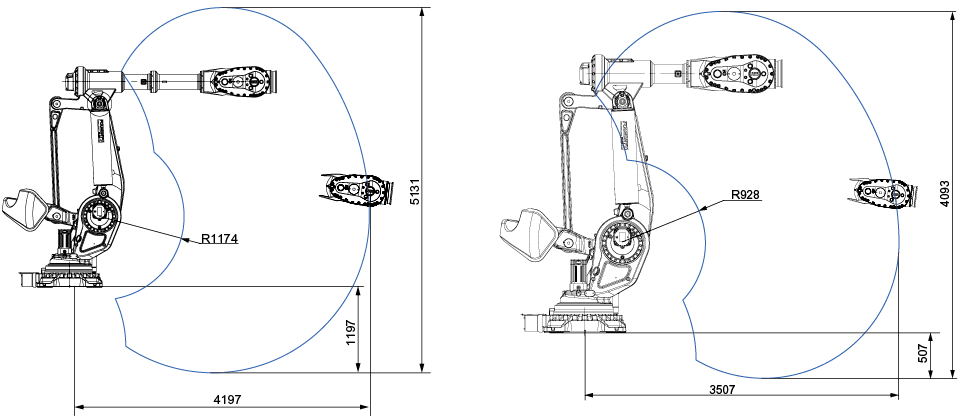

The largest robot ABB has ever made

In designing the IRB 8700 the focus was on delivering a very reliable robot with a low total cost of ownership. Through a combination of robust design elements, including simpler parts confi gurations where possible, ABB Robotics applied decades of engineering experience to combine the high performance customers require with low overall maintenance needs.

In addition, the IRB 8700 delivers 25% faster speeds than any other robot in this class size.

Features and benefits:

- High payloads up to 1000 kg with the wrist down

- 25% faster speeds than other robots in this size class

- Highly reliable with simplifi ed design and Foundry Plus 2 protection standard

- Built around LeanID for reduced wear on dress packs and ease of simulation

- Built using non-hazardous materials

Specification

| Robot versions | reach | handling capacity | center of gravity | wrist torque |

|---|---|---|---|---|

| Without Lean ID | ||||

| IRB 8700-800/3.50 | 3.50 m | 800 kg | 460 mm | 6043 Nm |

| IRB 8700-550/4.20 | 4.20 m | 550 kg | 460 mm | 5279 Nm |

| With Lean ID | ||||

| IRB 8700-800/3.50 | 3.50 m | 630 kg | 460 mm | 6043 Nm |

| IRB 8700-550/4.20 | 4.20 m | 475 kg | 460 mm | 5279 Nm |

| Extra loads can be mounted on all variants. 50 kg on upper arm and 500 kg on frame of axis 1. |

||||

| Number of axes | 6 | |||

| Protection | Complete robot IP67 | |||

| Mounting | Floor mounted | |||

| IRC5 Controller variants | Single cabinet | |||

Performance

| IRB 8700-800/3.50 | IRB 8700-550/4.20 | |

|---|---|---|

| Pos. repeatability RP | 0.05 mm | 0.08 mm |

| Path repeatability RT | 0.07 mm | 0.14 mm |

Maximum axis speed

| axis 1 | axis 2 | axis 3 | axis 4 | axis 5 | axis 6 | |

|---|---|---|---|---|---|---|

| IRB 8700-800/3.50 | 75°/s | 60°/s | 60°/s | 85°/s | 85°/s | 115°/s |

| IRB 8700-550/4.20 | 75°/s | 60°/s | 60°/s | 85°/s | 85°/s | 115°/s |

Electrical Connections

| Supply voltage | 200-600 V,50/60 Hz |

| Energy consumption ISO-Cube | 3.93 kW |

Physical

| Dimensions robot base | 1175 x 920 mm |

| Weight | 4527 - 4575 kg |

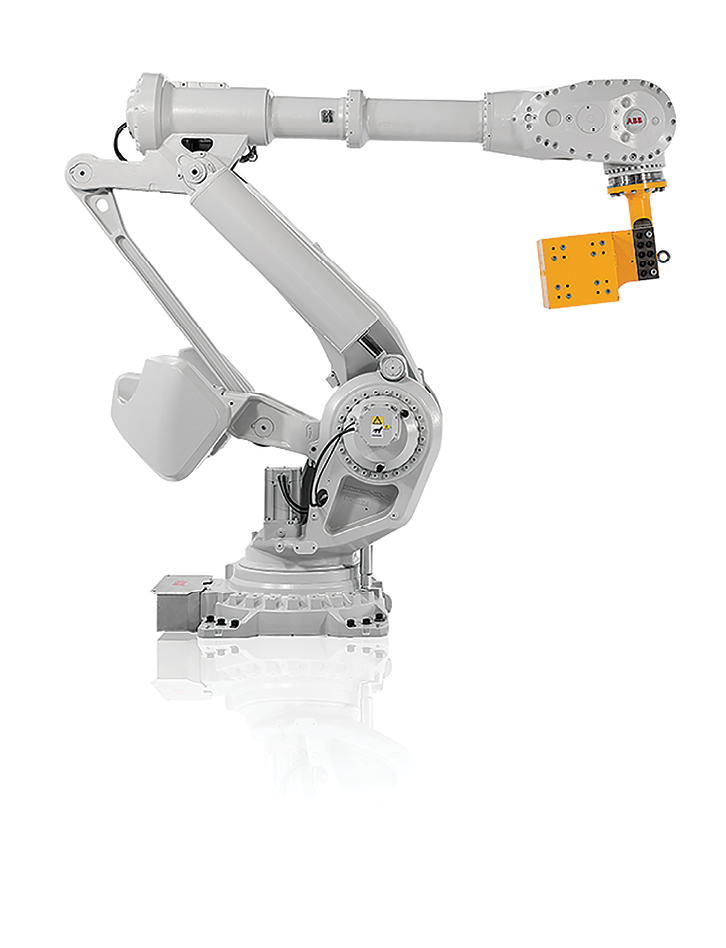

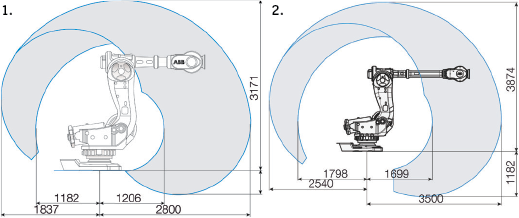

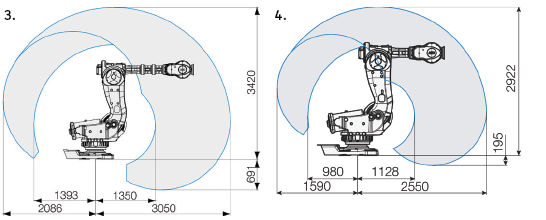

A new world of possibilities opens up with ABB’s power robot family.

It comes in several variants, up to 630 kg handling capacities. The IRB 7600 is ideal for weighty applications, regardless of industry. Characteristics such as high available torque and inertia capability, rigid design and powerful acceleration have earned this market leader its “Power Robot” title.

- Reliable – High production up time

- Security – A safe investment

- Fast – Short cycle times

- Accurate – Consistent parts quality

- Strong – Maximized utilization

- Robust – Harsh production environment

- Versatile – Flexible integration and production

Specification

| Robot versions | reach | handling capacity | center of gravity | max. wrist torque |

|---|---|---|---|---|

| IRB | ||||

| IRB 7600-500 | 2.55 m | 500 kg | 360 mm | 3010 Nm |

| IRB 7600-400 | 2.55 m | 400 kg | 512 mm | 3010 Nm |

| IRB 7600-340 | 2.8 m | 340 kg | 360 mm | 2750 Nm |

| IRB 7600-325 | 3.1 m | 325 kg | 360 mm | 2680 Nm |

| IRB 7600-150 | 3.5 m | 150 kg | 360 mm | 1880 Nm |

| (IRB 7600-150 loaded with 100 kg 1660 mm) | ||||

| Extra loads can be mounted on all variants 50 kg on upper arm and 550 kg on frame of axis 1. |

||||

| Number of axes | 6 | |||

| IRC5 Controller variants | Single cabinet, PMC | |||

Environment

| Ambient temperature for mechanical unit | |

|---|---|

| During operation | +5 °C (41 °F) up to +50 °C (122 °F) |

| During transportation & storage for short periods (max 24 h) | –25 °C (13 °F) up to +55 °C (131 °F) up to +70 °C (158 °F) |

| Relative humidity | Max 95% |

| Degree of protection | |

| Manipulator | Standard: IP67, Option: Foundry Plus 2 |

| Controller | Air cooled |

| Noise level | Max 73 dB (A) |

| Safety | Double circuits with supervision, emergency stops and safety functions, 3-positions enable device. |

| Emission | EMC/EMI-shielded |

Performance

| Axis working range | |

|---|---|

| Axis 1 Rotation | +180° to -180° |

| Axis 2 Arm | +85° to -60° |

| Axis 3 Arm | +60° to -180° |

| Axis 4 Wrist | +300° to -300° |

| Axis 5 Bend | +100° to -100° |

| Axis 6 Turn | +360° to -360° |

| Axis max speed | ||||

|---|---|---|---|---|

| 325/500 kg | 400 kg | 340 kg | 150 kg | |

| Axis 1 | 75°/s | 75°/s | 75°/s | 100°/s |

| Axis 2 | 50°/s | 60°/s | 60°/s | 60°/s |

| Axis 3 | 55°/s | 60°/s | 60°/s | 60°/s |

| Axis 4 | 100°/s | 100°/s | 100°/s | 100°/s |

| Axis 5 | 100°/s | 100°/s | 100°/s | 100°/s |

| Axis 6 | 160°/s | 160°/s | 160°/s | 190°/s |

Electrical Connections

| Supply voltage | 200-600 V,50/60 Hz |

Physical

| Dimensions robot base | 1206.5 x 791 mm |

| Weight | 2.400-2.450 kg |

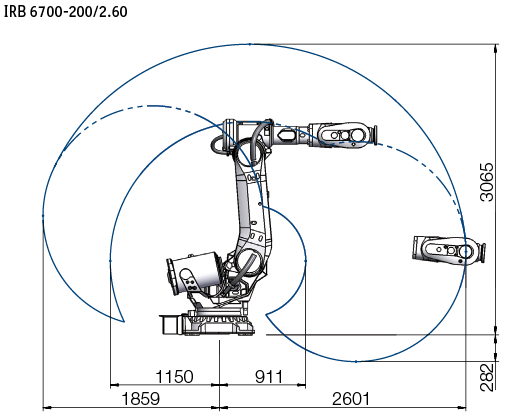

The IRB 6700 family of robots is a natural evolution following 40 years of large robot heritage at ABB.

This 7th generation of large ABB robots features a multitude of next generation improvements derived from intimate customer relationships and exhaustive engineering studies. The IRB 6700 is more robust than its predecessor and maintenance has been simplifi ed, making it the highest performing robot for the lowest total cost of ownership in the 150-300 kg class.

Features and benefits:

- Increased service intervals and decreased service times

- Longer uptime—mean time between failures: 400,000 hours

- Available with Lean ID for cost effectively increasing dress pack lifetimes

- More robust with a rigid structure and a new generation of motors and compact gearboxes

- Increased speed and shorter cycle times—on average 5 percent faster

- Improved accuracy and higher payloads

- Built to operate in the harshest environments—available with Foundry Plus 2 package

- 15 percent lower power consumption

Specification without LeanID

| Robot versions | reach | handling capacity | center of gravity | wrist torque |

|---|---|---|---|---|

| IRB | ||||

| 6700-200 | 2.60 m | 200 kg | 300 mm | 981 Nm |

| 6700-155 | 2.85 m | 155 kg | 300 mm | 927 Nm |

| 6700-235 | 2.65 m | 235 kg | 300 mm | 1324 Nm |

| 6700-205 | 2.80 m | 205 kg | 300 mm | 1263 Nm |

| 6700-175 | 3.05 m | 175 kg | 300 mm | 1179 Nm |

| 6700-150 | 3.20 m | 150 kg | 300 mm | 1135 Nm |

| 6700-300 | 2.70 m | 300 kg | 300 mm | 1825 Nm |

| 6700-245 | 3.00 m | 245 kg | 300 mm | 1693 Nm |

| Extra loads can be mounted on all variants 50 kg on upper arm and 250 kg on frame of axis 1. |

||||

| Number of axes | 6 | |||

| Protection | Complete robot IP67 | |||

| Mounting | Floor mounted | |||

| IRC5 Controller variants | Single cabinet, Panel Mounted Controller | |||

Specification with LeanID

| Robot versions | reach | handling capacity | center of gravity | wrist torque |

|---|---|---|---|---|

| IRB | ||||

| 6700-200 | 2.60 m | 175 kg | 300 mm | 981 Nm |

| 6700-155 | 2.85 m | 140 kg | 300 mm | 927 Nm |

| 6700-235 | 2.65 m | 220 kg | 300 mm | 1324 Nm |

| 6700-205 | 2.80 m | 200 kg | 300 mm | 1263 Nm |

| 6700-175 | 3.05 m | 155 kg | 300 mm | 1179 Nm |

| 6700-150 | 3.20 m | 145 kg | 300 mm | 1135 Nm |

| 6700-300 | 2.70 m | 270 kg | 300 mm | 1825 Nm |

| 6700-245 | 3.00 m | 220 kg | 300 mm | 1693 Nm |

| Extra loads can be mounted on all variants 50 kg on upper arm and 250 kg on frame of axis 1. |

||||

| Number of axes | 6 | |||

| Protection | Complete robot IP67 | |||

| Mounting | Floor mounted | |||

| IRC5 Controller variants | Single cabinet, Panel Mounted Controller | |||

Performance

| 6700-200 | 6700-155 | 6700-235 | 6700-245 | 6700-205 | 6700-175 | 6700-150 | 6700-300 | |

|---|---|---|---|---|---|---|---|---|

| Pos. repeatability RP (mm) | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

| Path repeatability RT (mm) | 0.06 | 0.12 | 0.08 | 0.12 | 0.08 | 0.12 | 0.14 | 0.07 |