The future is here

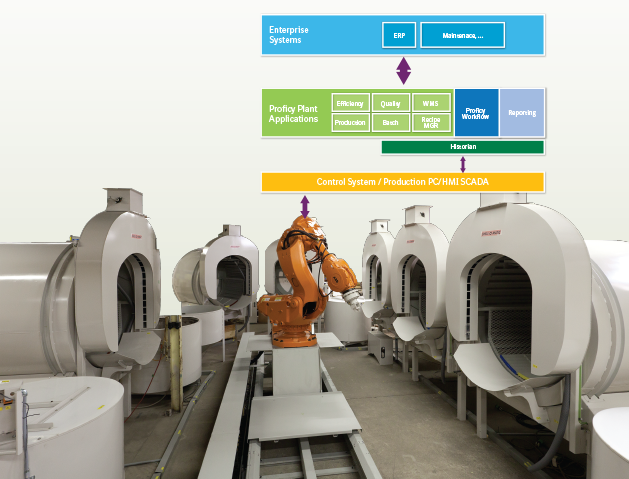

To build Manufacturing Execution Systems (MES) in foundries, Shell-O-Matic uses the Proficy suite of software from GE Digital.

GE Digital tracks all aspects of the manufacturing process. The software comes in modules, and Shell-O-Matic designs each customer’s system using just the modules required.

The Shell-O-Matic MES takes care of all automatic and manual manufacturing requirements for the plant of the future. The Shell-O-Matic MES can be used to manage the whole investment casting foundry from raw material management to casted part delivery.

The Shell-O-Matic team connects with customer engineering and management teams to tailor the MES system to the individual foundry’s needs.

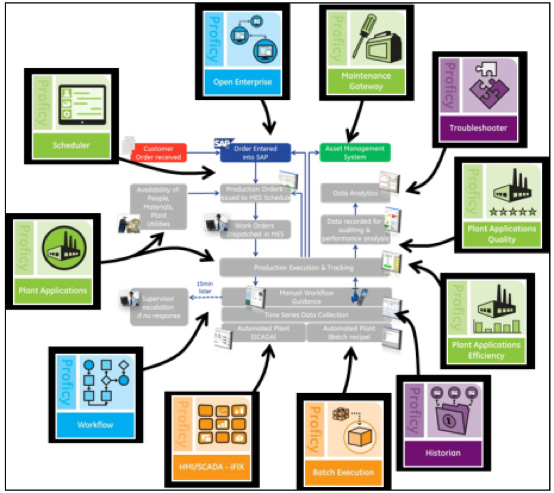

GE Proficy software architecture

The GE Proficy software architecture can work with any PLC platform to build a comprehensive MES system.

What sets this solution apart is the GE Cimplicity software – the HMI and Scada system implemented by the industrial PC.

Not only can the GE Cimplicity software take control of a shell-making robot cell, but it can also be deployed with other GE Digital products to take control of an entire factory through an Industry 4.0 system, or the Industrial Internet of Things (IIOT).

GE Cimplicity tools

The power of the GE Cimplicity software comes from its suite of tools.

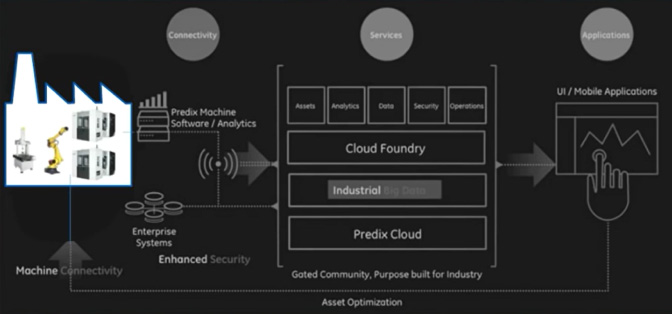

Predix

The operating system for the Industrial Internet, Predix powers the industrial app economy. With broad ecosystem support, Predix-based apps are unleashing new levels of performance for industrial assets.

Brilliant Manufacturing

Connecting streams of machine data to powerful analytics and people, GE Cimplicity tools provide industrial companies with a Brilliant Factory approach.

- Valuable insights to manage assets and operations more efficiently

- World-class talent and software capabilities

- Big gains in productivity, availability and longevity

Historian

The heart of the system is the Historian software, which records the status of all probes and variables in the system. That data is then used by the other Proficy modules to create the functions an MES system.

Don’t be fooled by its small footprint – Historian can scale to support hundreds of users and millions of individual machine data points.

- Provides administration and trending capabilities following install and tag configuration

- Supports high availability and data-redundancy needs through out-of-the-box data-mirroring

MES elements

The MES connects the streams of machine data to powerful analytics and people, providing industrial companies with valuable insights to manage assets and operations more efficiently.

The MES is made up of a series of GE Digital modules, including:

- Historian – Central information storage for all data coming from the plant. Everything starts with data, making this the heart of your entire system

- Open Enterprise – Connects the MES to any ERP on the market, showing real-time order status as well as feeding all orders and data to the MES to handle their execution in the automated factory

- Scheduler – Compares customer orders with availability of staff, material and equipment in real-time to enable live interactive production planning. Also guides material flow across the factory to ensure manufacturing cells are fed the right materials and recipes to make the right products

- Plant Applications – As the brain of the MES, it performs three core functions: OEE (downtime/efficiency), Quality (SPC), and Production (traceability, mass balance, label-printing, interface to ERP)

- Workflow – Simplifies tasks for operators/technicians by guiding them through required steps of their product processes

- HMI/Scada – Provides various visualization tools throughout the system

- CSense – Pinpoints the causes of production and process variations and executes actions to notify or automatically eliminate production stoppages or quality issues before they happen

- Maintenance Gateway – Allows the MES to connect with any Maintenance system on the market to streamline all equipment maintenance and track equipment status to automatically dispatch tasks to the maintenance crew