Enhancing robot and machine safety

Ensuring safe interaction between industrial robots and their operators is an essential part of a high-functioning integrated system.

At Shell-O-Matic, we work with the ANSI/RIA R15.06 (Industrial Robot and Robot Systems Safety Requirements), ISO 10218 (Safety requirements for industrial robots) and ISO 12100/ISO 13849 (Safety of Machinery) guidelines to provide comprehensive safety solutions specific to our customers’ needs.

Three-step process:

- Generating a risk assessment matrix of your machinery, as required by the relevant standards

- Analyzing all interactions between humans and machines

- Providing risk-reduction strategies

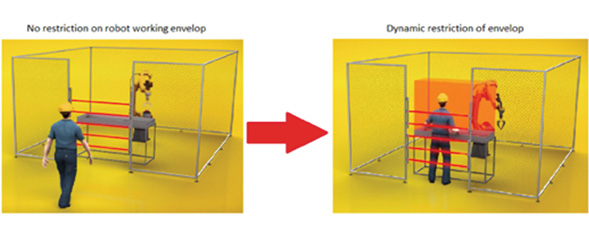

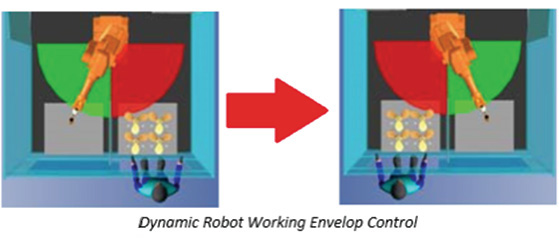

Dynamic control of robot working envelop

Controlling the robot’s working envelop (its reach) is the first step to creating a dynamic and safe collaboration between the robot and an operator.

Robot manufacturers offer software options to dynamically control the robot working envelop as a function of system status.

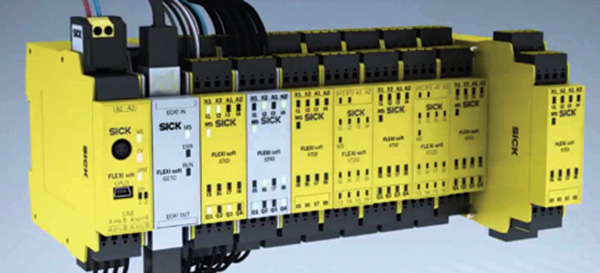

Programmable safety controller

An optional part of the Shell-O-Matic Supervisory system, the programmable safety controller allows for more complex safety logic.

Advantages of the programmable safety controller:

- Manage the various safety devices and functions required with a robotic cell

- Scalable

- Reprogrammable, so it can evolve the logic or system with changing customer needs

- Communicates at the machine network level

- Share safety system status

- Adjust PLC control logic

- Display appropriate messages on the HMI screen

Safety devices

Shell-O-Matic can create a custom safety system tailored to customer needs. The system can be connected to various safety devices, including:

- Light curtains

- E-stop buttons

- Two-hands controls

- Area scanner

- Safety mats

This system allows Shell-O-Matic to deliver not only a new state-of-the-art safety system, but also to retrofit or upgrade existing robotic cell safety systems.