From the shell-making process to the ‘zero-touch’ factory

Shell-O-Matic offers a range of supervisory systems that are compatible with the Industrial Internet of Things (IIOT or Industry 4.0), giving our customers the level of factory automation best suited to their needs.

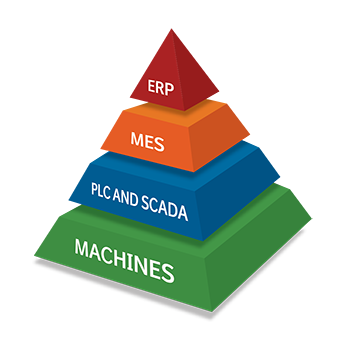

These systems take advantage of the new Manufacturing Execution System (MES) trend to connect the machine automation level to the company Enterprise Resource Planning (ERP) system.

Advantages of connecting these systems include:

- Ability to create “zero touch” factories by connecting machines to automate business/manufacturing processes

- Records of process variability with complete traceability

- Enhanced troubleshooting tools

- Better process standardization with more complete recipe and customer requirement flow at the machine and control level

- Better production flow control over the factory

- Real-time feedback on the parts and lots status

- More accurate scheduling

- Improved, easy-to-create and more precise KPI (key performance indicator)

- Better tracking of machine usage

- Enhanced preventive maintenance tools

- More data available for the quality system and better product traceability