At Shell-O-Matic, we know applying stucco can be a delicate operation.

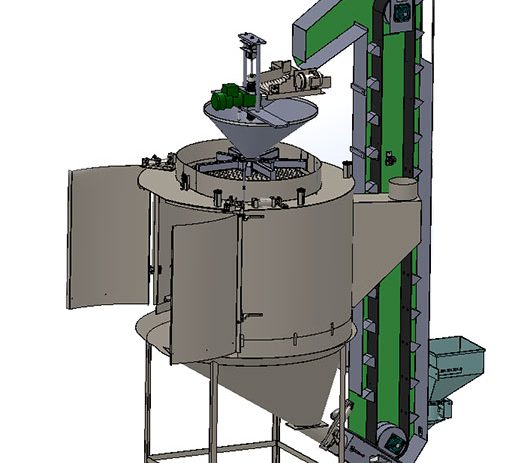

Its rain density is generous and adjustable to perfectly meet your process requirement. In every detail of its design we paid attention to preventing the sand grains from being crushed between moving steel surfaces in order to maintain the sand granulometry at all costs. The result is our high-end sander delivering the perfect rainfall every time. We have been perfecting this design for over 40 years. The result is a sander with unmatched ease of sand exchange, large and generous rainfall area and proven reliability. Our product line includes 6 models with rainfall area diameter of 30’’/760 mm, 38’’/960 mm, 48’’/1220 mm, 58’’/1470 mm, 64’’/1670 mm and 78’’/1980 mm.

The key features of these sanders are:

- Dense and uniform sand distribution over a large area to ensure fast stuccoing.

- Automatic, continuous sand cleaning is built-in.

- Rugged design with industrial parts available worldwide.

- Rapid change over from one stucco to another; fine or coarse sand.

- Clamshell-type swing doors contain dust and sand during stuccoing operation.

- Dust collector system to avoid toxic dust from getting in the shell room environment.

- Bottom receiving bin can be replaced by a fluidizer to reduce equipment floor space while improving stucco-applying flexibility.